Titanium And Aluminum Alloy . aluminum loses its original properties at around 150°c, whereas titanium alloys maintain good mechanical performance at approximately 500°c. this article explores the fascinating world of titanium and aluminum alloys, revealing their unique properties and crucial roles in aerospace. compare the chemical composition, mechanical properties, cost, and applications of titanium and aluminum alloys. compare the properties, advantages and disadvantages of titanium and aluminum, two popular metals used in various. This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages. This article contains comparison of key thermal and atomic properties of aluminium and titanium, two. learn about the differences between titanium and aluminum to determine which material is best for your manufacturing project.

from www.steeltube.biz

this article explores the fascinating world of titanium and aluminum alloys, revealing their unique properties and crucial roles in aerospace. compare the properties, advantages and disadvantages of titanium and aluminum, two popular metals used in various. aluminum loses its original properties at around 150°c, whereas titanium alloys maintain good mechanical performance at approximately 500°c. This article contains comparison of key thermal and atomic properties of aluminium and titanium, two. learn about the differences between titanium and aluminum to determine which material is best for your manufacturing project. This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages. compare the chemical composition, mechanical properties, cost, and applications of titanium and aluminum alloys.

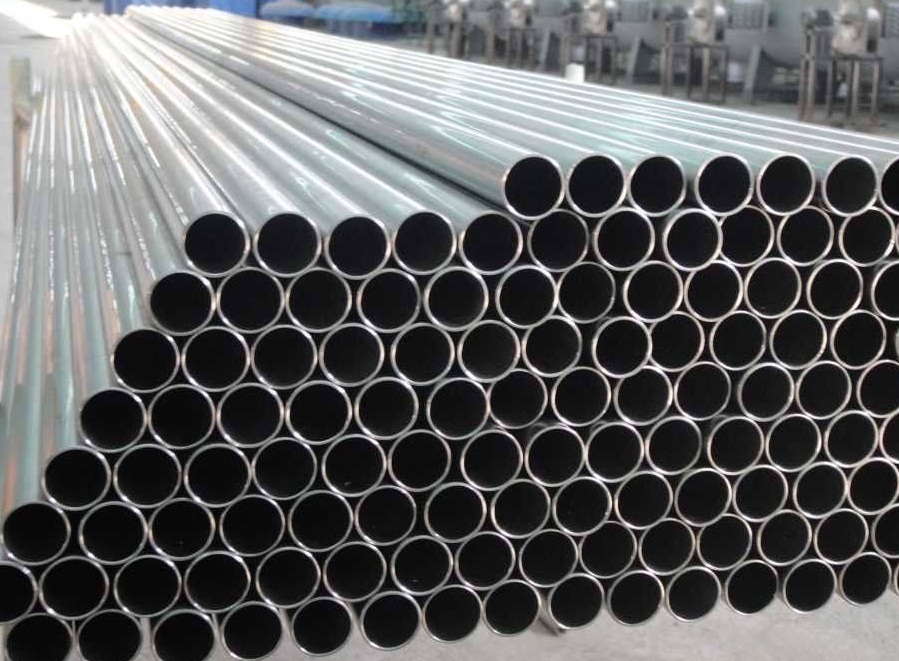

ASTM B861 Titanium and Titanium Alloy Seamless Pipe, Seamless Tube

Titanium And Aluminum Alloy This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages. compare the chemical composition, mechanical properties, cost, and applications of titanium and aluminum alloys. This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages. aluminum loses its original properties at around 150°c, whereas titanium alloys maintain good mechanical performance at approximately 500°c. learn about the differences between titanium and aluminum to determine which material is best for your manufacturing project. compare the properties, advantages and disadvantages of titanium and aluminum, two popular metals used in various. this article explores the fascinating world of titanium and aluminum alloys, revealing their unique properties and crucial roles in aerospace. This article contains comparison of key thermal and atomic properties of aluminium and titanium, two.

From prashaantsteel.com

Titanium Vs. Aluminum Which Metal Should You Use? Prashaant Steel Titanium And Aluminum Alloy This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages. This article contains comparison of key thermal and atomic properties of aluminium and titanium, two. learn about the differences between titanium and aluminum to determine which material is best for your manufacturing project. aluminum. Titanium And Aluminum Alloy.

From www.refractorymetal.org

Titanium Aluminum Alloy Preparation & Application Titanium And Aluminum Alloy This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages. compare the properties, advantages and disadvantages of titanium and aluminum, two popular metals used in various. this article explores the fascinating world of titanium and aluminum alloys, revealing their unique properties and crucial roles. Titanium And Aluminum Alloy.

From dxojqpzyr.blob.core.windows.net

What Is Titanium Alloy at Sandra Medrano blog Titanium And Aluminum Alloy learn about the differences between titanium and aluminum to determine which material is best for your manufacturing project. this article explores the fascinating world of titanium and aluminum alloys, revealing their unique properties and crucial roles in aerospace. compare the chemical composition, mechanical properties, cost, and applications of titanium and aluminum alloys. This makes them highly suitable. Titanium And Aluminum Alloy.

From dxoifiawn.blob.core.windows.net

Titanium Alloy Material Composition at Debra King blog Titanium And Aluminum Alloy learn about the differences between titanium and aluminum to determine which material is best for your manufacturing project. This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages. compare the properties, advantages and disadvantages of titanium and aluminum, two popular metals used in various.. Titanium And Aluminum Alloy.

From www.steeltube.biz

ASTM B861 Titanium and Titanium Alloy Seamless Pipe, Seamless Tube Titanium And Aluminum Alloy learn about the differences between titanium and aluminum to determine which material is best for your manufacturing project. This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages. compare the properties, advantages and disadvantages of titanium and aluminum, two popular metals used in various.. Titanium And Aluminum Alloy.

From www.china-machining.com

Titanium vs. Aluminum Which Lightweight Metal is Best? Titanium And Aluminum Alloy This article contains comparison of key thermal and atomic properties of aluminium and titanium, two. learn about the differences between titanium and aluminum to determine which material is best for your manufacturing project. this article explores the fascinating world of titanium and aluminum alloys, revealing their unique properties and crucial roles in aerospace. compare the properties, advantages. Titanium And Aluminum Alloy.

From huicheng.org

Aluminium Titanium Master Alloy Hui Cheng Titanium And Aluminum Alloy this article explores the fascinating world of titanium and aluminum alloys, revealing their unique properties and crucial roles in aerospace. aluminum loses its original properties at around 150°c, whereas titanium alloys maintain good mechanical performance at approximately 500°c. compare the chemical composition, mechanical properties, cost, and applications of titanium and aluminum alloys. learn about the differences. Titanium And Aluminum Alloy.

From ultraflexpower.com

Preheating of Titanium & Aluminum Alloys UltraFlex Power Technologies Titanium And Aluminum Alloy aluminum loses its original properties at around 150°c, whereas titanium alloys maintain good mechanical performance at approximately 500°c. this article explores the fascinating world of titanium and aluminum alloys, revealing their unique properties and crucial roles in aerospace. compare the chemical composition, mechanical properties, cost, and applications of titanium and aluminum alloys. This article contains comparison of. Titanium And Aluminum Alloy.

From www.slideserve.com

PPT Titanium and titanium alloys PowerPoint Presentation ID1622847 Titanium And Aluminum Alloy compare the properties, advantages and disadvantages of titanium and aluminum, two popular metals used in various. aluminum loses its original properties at around 150°c, whereas titanium alloys maintain good mechanical performance at approximately 500°c. this article explores the fascinating world of titanium and aluminum alloys, revealing their unique properties and crucial roles in aerospace. This article contains. Titanium And Aluminum Alloy.

From www.hexonmetal.com

Titanium alloy Titanium And Aluminum Alloy aluminum loses its original properties at around 150°c, whereas titanium alloys maintain good mechanical performance at approximately 500°c. compare the properties, advantages and disadvantages of titanium and aluminum, two popular metals used in various. This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages.. Titanium And Aluminum Alloy.

From dxojqpzyr.blob.core.windows.net

What Is Titanium Alloy at Sandra Medrano blog Titanium And Aluminum Alloy This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages. aluminum loses its original properties at around 150°c, whereas titanium alloys maintain good mechanical performance at approximately 500°c. compare the chemical composition, mechanical properties, cost, and applications of titanium and aluminum alloys. This article. Titanium And Aluminum Alloy.

From www.rankred.com

Titanium Alloy Types Properties Applications RankRed Titanium And Aluminum Alloy aluminum loses its original properties at around 150°c, whereas titanium alloys maintain good mechanical performance at approximately 500°c. This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages. compare the chemical composition, mechanical properties, cost, and applications of titanium and aluminum alloys. This article. Titanium And Aluminum Alloy.

From www.bjhighstar.com

Application of titanium alloy in automobile TITANIUM METAL Titanium And Aluminum Alloy aluminum loses its original properties at around 150°c, whereas titanium alloys maintain good mechanical performance at approximately 500°c. compare the chemical composition, mechanical properties, cost, and applications of titanium and aluminum alloys. This article contains comparison of key thermal and atomic properties of aluminium and titanium, two. compare the properties, advantages and disadvantages of titanium and aluminum,. Titanium And Aluminum Alloy.

From dxojqpzyr.blob.core.windows.net

What Is Titanium Alloy at Sandra Medrano blog Titanium And Aluminum Alloy This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages. this article explores the fascinating world of titanium and aluminum alloys, revealing their unique properties and crucial roles in aerospace. learn about the differences between titanium and aluminum to determine which material is best. Titanium And Aluminum Alloy.

From www.yubisteel.com

Titanium Grade 4 (UNS R50700) Stainless, Steel, Aluminum, Nickel Titanium And Aluminum Alloy compare the properties, advantages and disadvantages of titanium and aluminum, two popular metals used in various. This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin of aircraft rear fuselages. compare the chemical composition, mechanical properties, cost, and applications of titanium and aluminum alloys. learn about the. Titanium And Aluminum Alloy.

From www.dierk-raabe.com

Metallurgical Materials Science and Alloy Design Mechanical Titanium And Aluminum Alloy this article explores the fascinating world of titanium and aluminum alloys, revealing their unique properties and crucial roles in aerospace. learn about the differences between titanium and aluminum to determine which material is best for your manufacturing project. compare the chemical composition, mechanical properties, cost, and applications of titanium and aluminum alloys. This article contains comparison of. Titanium And Aluminum Alloy.

From www.nuclear-power.com

Titanium Alloys Characteristics and Uses Titanium And Aluminum Alloy compare the properties, advantages and disadvantages of titanium and aluminum, two popular metals used in various. learn about the differences between titanium and aluminum to determine which material is best for your manufacturing project. This article contains comparison of key thermal and atomic properties of aluminium and titanium, two. this article explores the fascinating world of titanium. Titanium And Aluminum Alloy.

From www.refractorymetal.org

An Overview of Nickeltitanium Alloy Refractory Metals and Alloys Titanium And Aluminum Alloy this article explores the fascinating world of titanium and aluminum alloys, revealing their unique properties and crucial roles in aerospace. learn about the differences between titanium and aluminum to determine which material is best for your manufacturing project. This makes them highly suitable for use in compressor discs and blades of aircraft engines, as well as the skin. Titanium And Aluminum Alloy.